Customer Qualification Plant (CQP) - Norway

FREYR’s Customer Qualification Plant (CQP) is located in a 13,000 m2 building in Mo i Rana, Northern Norway.

The CQP functions as a full-sized demonstration production line, at the actual physical size of a industrial scale production line in commercial operations. This facility will focus on product development and refinement and will allow us to create sample cells for our customers and test different materials over time.

It will also act as a training ground for our operators, who will one day staff our commercial giga factories.

Video tour of FREYR's Customer Qualification Plant (CQP) and Processes

The CQP consists of three assets:

- An industrial scale production line

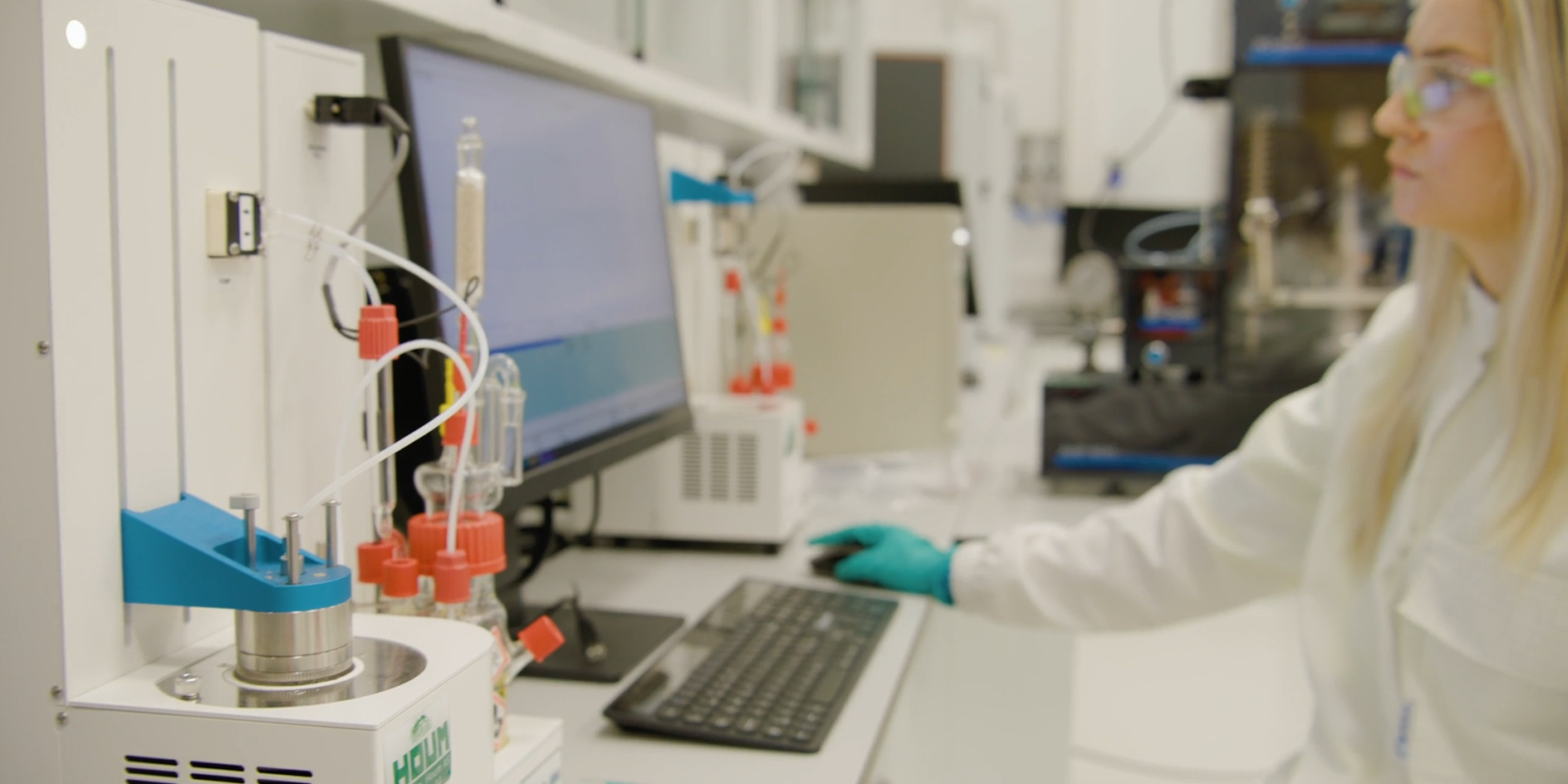

- Quality test lab

- Testcenter for life cycle testing of battery cells

Production Technology

FREYR Battery licenses Battery cell Technology from US based 24M Technologies, which was a spin-off from MIT. The 24M production process differs from conventional battery cell production, with a reduced number of production steps.

Take a fascinating journey inside FREYR's cutting-edge Customer Qualification Plant (CQP) in Norway, witness the intricate process design that will enable us to manufacture advanced battery cells for clean energy, and meet the dedicated team shaping a sustainable future.

Immerse yourself in the remarkable story of FREYR Battery's Customer Qualification Plant (CQP) in Mo i Rana, Northern Norway. This video takes you on a captivating journey, highlighting the transformation of the CQP from a vast, empty hall to a cutting-edge 13,000 m² facility, preparing to shape the future of battery technology.