Electric Vehicle (EV)

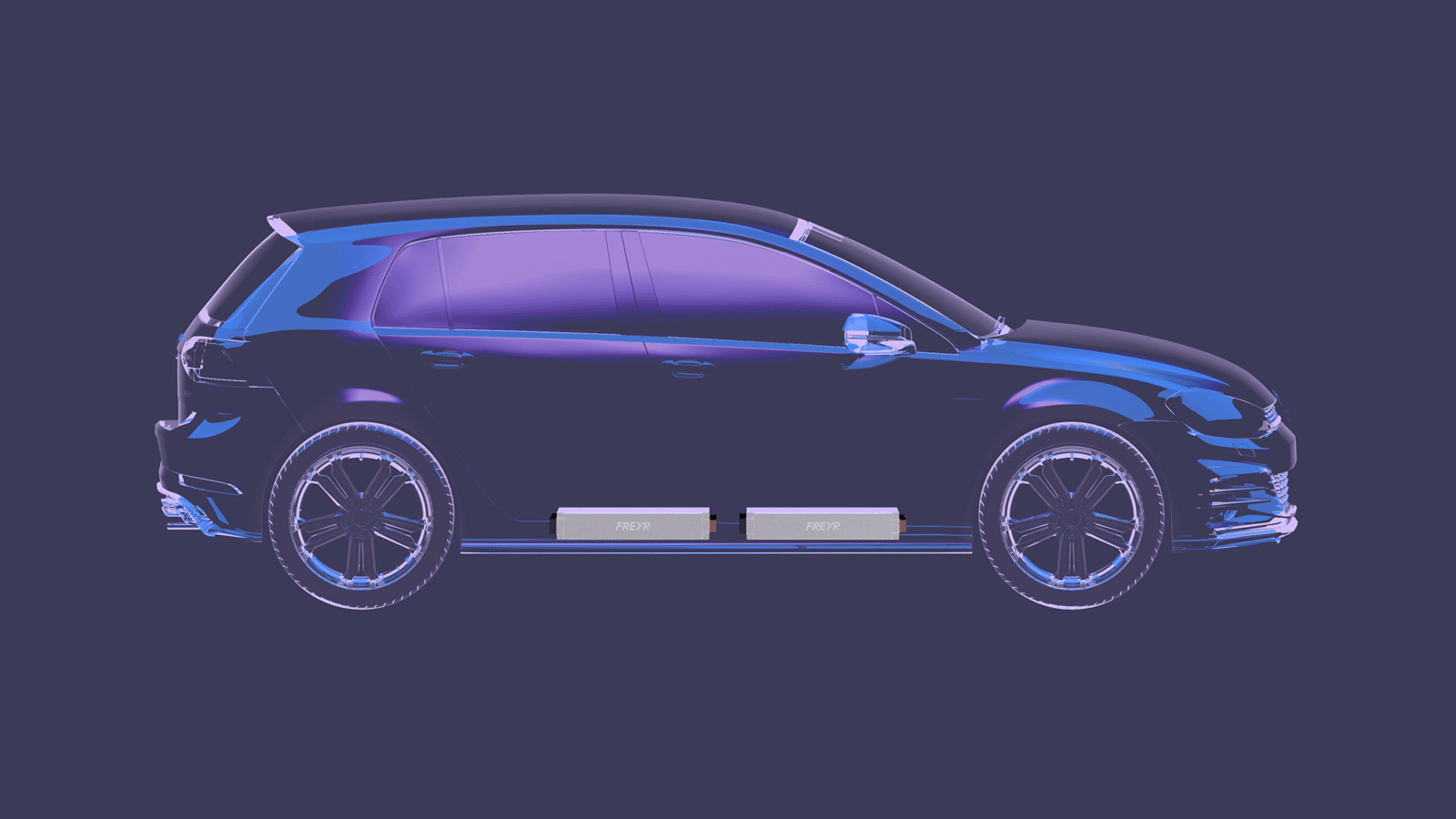

FREYR’s primary differentiating factors for EV battery cell production at scale is driving conversion costs by aiming to establish a full Nordic supply chain and utilizing 24M technology that offers a potential meaningful reduction in processes and labor compared to conventional solutions.

Unlocking Nordic’s supply chain based on CO2-free energy, emission free transportation and logistics solutions with leading circular economy principles in production resulting in large scale cell recycling solutions.

The combination of 24M technologies and low carbon sourced raw materials will make our batteries a clean circular solution for an environmentally friendly world

24M solves the grand challenge of energy storage with the invention of the semisolid lithium-ion battery, a revolutionary technology for the architects of our energy future. Credit: 24M Technologies

Gery Bonduelle currently serves as Global Revenue of FREYR. He has close to 30 years of experience within the battery industry. Prior to joining FREYR, Mr. Bonduelle held multiple positions at EnerSys, most recently as Sales Vice President EMEA and APAC and prior to that as Vice President Sales Reserve Power EMEA.

Mr. Bonduelle holds a B.S. and an M.Sc. in Mechanical Engineering from ENIM University.