Supply chain and logistics

FREYR plans to source battery materials with the lowest possible carbon footprint and socially responsible production. We believe that developing a ‘green’ value chain is closely tied to the supply of materials sourced locally from the Nordic region, produced using renewable energy and minimal distances needed in transport.

Supply chain

FREYR will seek to actively contribute to creating sustainable production materials for the lithium-ion battery industry by enabling the development of production facilities for active materials in the Nordic countries, based on renewable energy.

We are engaging with European suppliers to develop supply agreements for active materials. European, and especially Nordic-based materials are manufactured with a lower CO₂ emissions profile than materials sourced from other regions of the world.

Some materials will likely be sourced globally. FREYR will require that suppliers certify the materials are produced in a responsible manner, outside conflict areas, and under conditions showing due respect to international labor standards and the environment.

Logistics

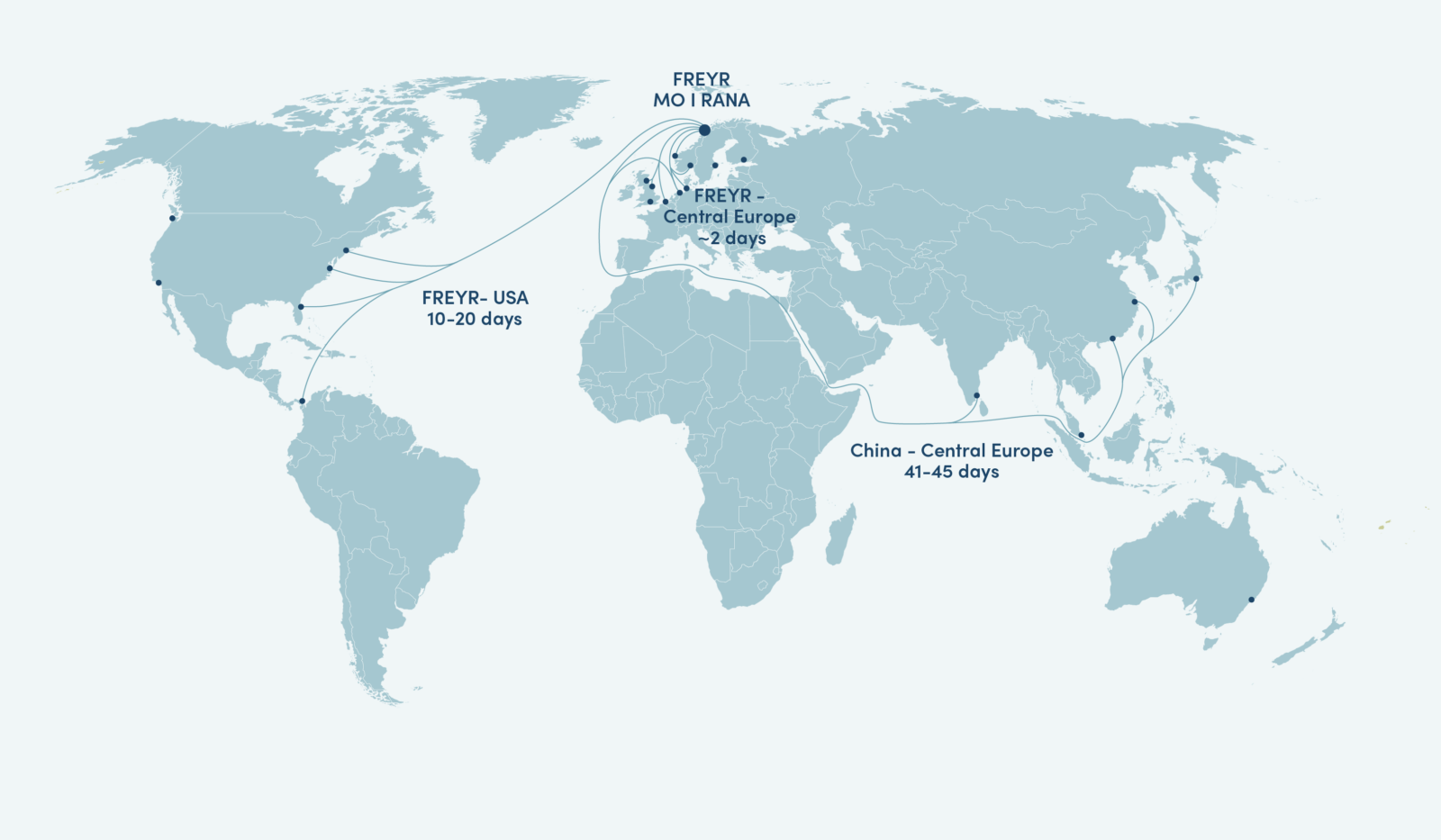

FREYR is developing a logistics model to optimize the transportation of raw materials and finished products to and from our facilities in Rana, Norway.

Mo i Rana has a large port, railroad connection, airport and is located along European highways E6 (Norway) and E12 (connecting Norway to Sweden). These offer multiple ways that materials can be imported and how FREYR battery solutions can be exported to customers worldwide.

A container ship can reach Rotterdam, Europe's biggest port, in two days from the ice-free port in Mo i Rana. We can also ship finished products to Europe by rail or truck within a similar timeframe. This is significantly shorter and more environmentally friendly, compared to shipping from producers in Southeast Asia to Western Europe or to the East Coast of the United States. FREYR’s close vicinity to European and American customers will minimize transportation-related emissions per battery produced, compared to those being transported from Asia.

Our local logistics model includes the possibility of using electric forklifts and trucks at the production facilities in order to reduce emissions.