FREYR drives development and production of next-generation battery cell technology

Sep 19, 2023

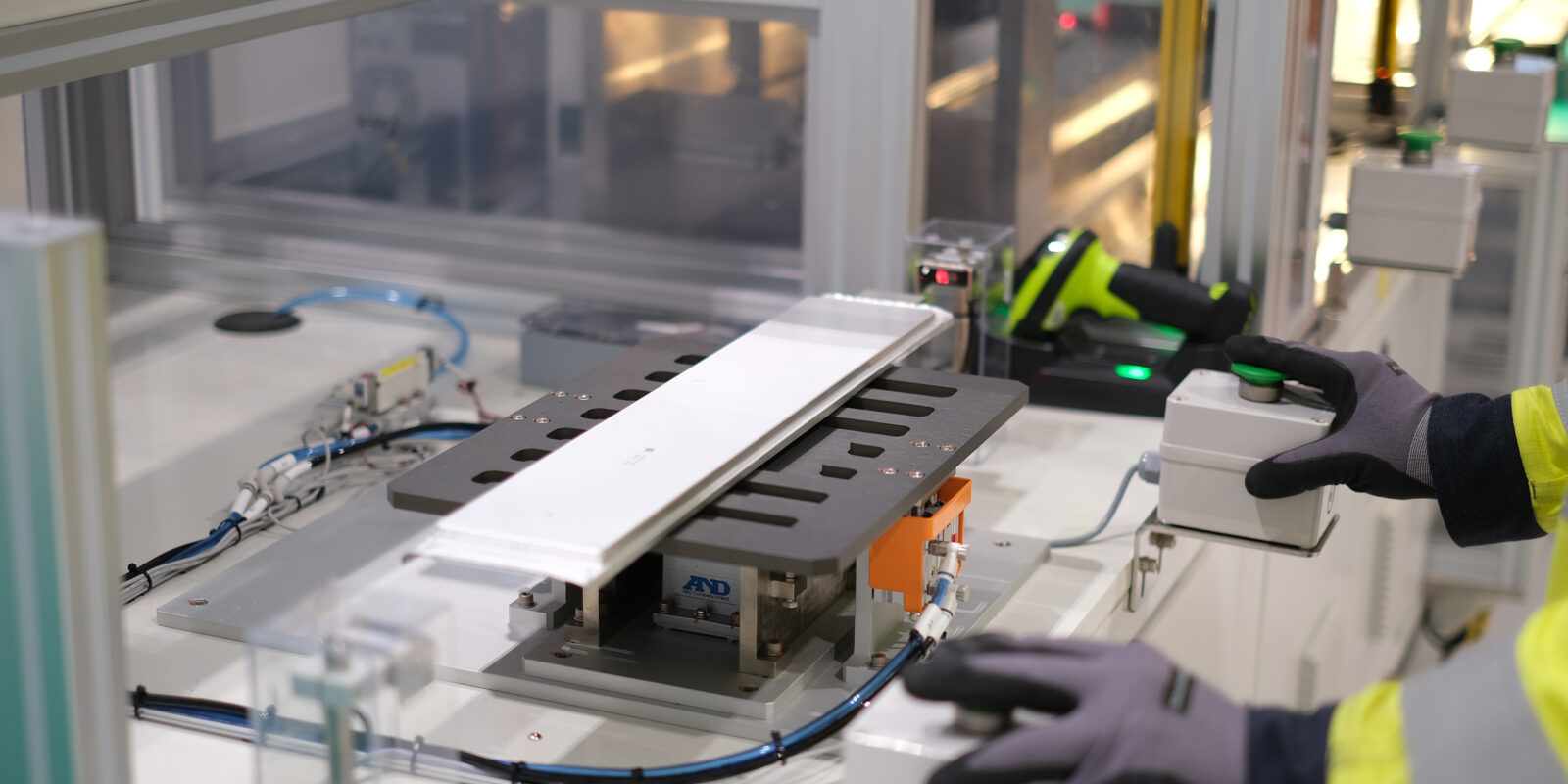

FREYR Battery is ramping up production at the Customer Qualification Plant (CQP) in Mo i Rana, Norway, taking the U.S. technology from 24M Technologies to GWh scale.

Back in November 2020, FREYR selected 24M as technology partner for lithium-ion cell manufacturing with their SemiSolidTM platform. The MIT-spinoff founded by Dr. Yet-Ming Chiang is already commercially introduced at MWh-scale in Asia, which was a key aspect in the selection process.

- The 24M technology is fundamentally improving and simplifying the production process compared to conventional Li-ion battery cells. We expect lower costs, lower energy consumption, and increased capacity per employee, says Dr. Andreas Bentzen, EVP Technology in FREYR, who has with close to 20 years of experience from the solar industry, including REC Group in Silicon Valley and Otovo which he also Co-Founded.

– The products we develop and put in production at the CQP will be inherently safer and more reliable, offer easier waste recovery and end-of-life recycling, as well as consuming less inactive materials.

Simplified manufacturing processes

FREYR is using a SemiSolidTM platform, where that the anode and cathode slurry has a clay-like composition much thicker than conventional Li-ion production, avoiding the needs for solvent evaporation and recovery. The number of unique process steps are significantly reduced, and the usage of inactive materials is much lower.

- Manufacturing Li-ion battery cells is a fast-moving production process with a high degree of automation and digitalization. We are using advanced technologies to drive accelerated learning in both our development and manufacturing processes, improving performance, and reducing waste, says Bentzen.

The simplified manufacturing process results in next-generation battery cells with several competitive advantages:

- The reduction in processing steps enables faster speed to manufacturing and reduced factory footprint.

- The reduction in capital expenditures needed and ability to use existing industrial buildings provides brownfield benefits.

- A simpler production process reduces energy consumption significantly.

- Increased automation and digitalization reduce the labour needed to produce the same output.

Energy Storage Systems (ESS)

FREYR is working together with licensee partners to bring next-generation SemiSolidTM technology to scale. The manufacturing platform is flexible to changes in electrochemistry and supports several cell technologies, with immediate focus on LFP based chemistries. This makes the SemiSolidTM technology applicable to a wide range of applications.

- The SemiSolidTM platform produces battery cells with an energy density and a larger electrode design most suitable for ESS solutions, which is the first market we are addressing, says Bentzen.

Advanced R&D

FREYR is working hard to develop the technology even further, with laboratory facilities both in Japan and Norway, in addition to extensive R&D collaboration with 24M and other partners.

– We are exploring further improvements to the SemiSolidTM platform, in order to increase the benefits out of its advantages. New materials, new manufacturing processes, and new cell designs are all part of our longer-term roadmap, Bentzen explains.

– By being smarter and bolder we will maintain and increase our competitive advantages, and ultimately contribute to a better, cleaner, and more sustainable future. That is why we are here in the first place.